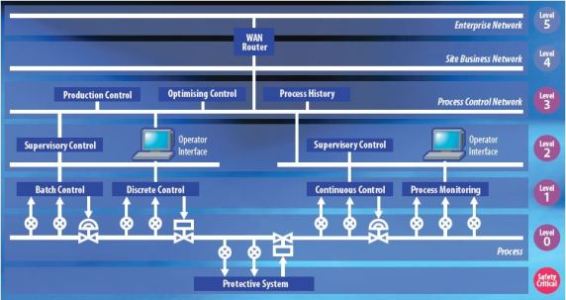

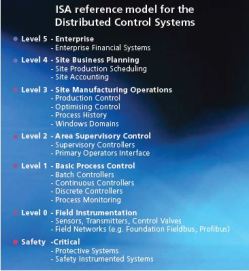

CERN needs to define approaches

for achieving the dual goals of connecting its

operational network to the Internet while at the

same time keeping its industrial control systems

secure from external and internal attacks. With this

in mind, the ISA-99 international cyber security

standard was adopted as a reference model to define

a set of implementation guidelines and a list of

security robustness criteria applicable to any

network device. Device security represents a key

link in the defense-in-depth concept (See Figure ISA

reference model for the Distributed Control

Systems), as some attacks will inevitably penetrate

security boundaries and thus require further

protection measures.

Since no solutions based on security standards

are available on the market, a wide investigation of

the current cyber security testing techniques and

systems has been performed in the first phase of the

project. The team reviewed the

Wurldtech’s "Achilles Satellite" product, a powerful

testing platform, and successfully used it to

analyse and evaluate the effectiveness of different

testing techniques. However, to overcome this

platform’s proprietary aspects and limitations in

terms of supported network protocols and attack

techniques customisation support, the Test-bench for

Robustness of Industrial Equipments ("TRoIE") was

designed and implemented. TRoIE aims at discovering

possible PLC vulnerabilities through Ethernet

communications. Such tests must not be confused with

functional testing, where only valid operations are

performed to cover all the possible "not malicious,

but operating" scenarios. On the contrary, it is

necessary to detect possible anomalies arising from

an incorrect handling of corrupt communication

channels. This approach has already been proven by

the valuable findings obtained during the analysis

of Siemens S7 PLC ranges. Thanks to this analysis,

it was possible to report critical anomalies in the

software stack to Siemens and directly contribute to

improving the security level and robustness of their

PLCs. These initial encouraging results have

motivated the team to continue following and

expanding this approach for the future of the

openlab collaboration.

Since no solutions based on security standards

are available on the market, a wide investigation of

the current cyber security testing techniques and

systems has been performed in the first phase of the

project. The team reviewed the

Wurldtech’s "Achilles Satellite" product, a powerful

testing platform, and successfully used it to

analyse and evaluate the effectiveness of different

testing techniques. However, to overcome this

platform’s proprietary aspects and limitations in

terms of supported network protocols and attack

techniques customisation support, the Test-bench for

Robustness of Industrial Equipments ("TRoIE") was

designed and implemented. TRoIE aims at discovering

possible PLC vulnerabilities through Ethernet

communications. Such tests must not be confused with

functional testing, where only valid operations are

performed to cover all the possible "not malicious,

but operating" scenarios. On the contrary, it is

necessary to detect possible anomalies arising from

an incorrect handling of corrupt communication

channels. This approach has already been proven by

the valuable findings obtained during the analysis

of Siemens S7 PLC ranges. Thanks to this analysis,

it was possible to report critical anomalies in the

software stack to Siemens and directly contribute to

improving the security level and robustness of their

PLCs. These initial encouraging results have

motivated the team to continue following and

expanding this approach for the future of the

openlab collaboration.

Software engineering

The process visualisation and control system PVSS

is used at CERN for large distributed control

systems, some with more than 150 computers. In the

first year of collaboration between Siemens/ETM (a

subsidiary of Siemens) and CERN, the PVSS project

focused on two main areas. First, learning PVSS in

depth. Second, starting to use the acquired

knowledge for improvements and testing of upcoming

features at CERN. To attain these objectives, the

team concentrated on four main activities. The

Oracle Archiver is a solution in PVSS for storing

and retrieving historical data. CERN has been one of

the main users of this feature, requiring an

excellent performance and stability when faced with

large volumes of data and high update frequencies.

As a learning task, a number of critical issues and

improvements raised by CERN users were solved. The

result was the incorporation of code written at

openlab in a subsequent patch of PVSS released by

ETM.

Users of PVSS at CERN use SVN (a

version control system) as a revision control system

for their projects. The PVSS development environment

did not have SVN integrated, forcing users to

control their project revisions using external

tools. Within the openlab framework, a SVN plugin

for the development environment was prototyped and

then used as a showcase to other ETM clients.

The PVSS version reporting tool (PVR) is a new

tool that is now available to ETM, and in use at

CERN. Typically, users requiring support when using

PVSS report their problems through e-mail or issue

tracking systems. However, a lot of systematic

information is very often required and not sent

manually when using this report mechanism. Using the

PVSS Version Report Tool instead, a lot of typical

information, which can be as simple as the Operating

System or PVSS version number or free disk space and

project dependencies, is automatically sent. This

provides a much more efficient mechanism for

reporting.

One of the constant feature requests by CERN

users is Web Support in PVSS. ETM provided a Web

plugin with the 3.9 release, which has still not

been adopted at CERN. In order to test it for

possible future use, and provide a testing ground to

ETM with the usual CERN extreme requirements, the

Web plugin was tested in the openlab scope, tackling

both functional and performance aspects of the novel

feature. A full report with analysis of issues of

concern was sent back to ETM, providing information

on aspects to be improved before adoption at CERN.

Step7 Openness and

Deployment

The Step7 Openness and Deployment

project is sub-divided into two major topics. The

first topic focuses on the issues related to the

deployment of Step7 in large-scale environments in

an automated way. The second one concentrates on the

issue of bringing in software engineering concepts

and capabilities to enhance the features of the

Step7 software stack.

In 2009/2010, deployment of Step7

in large-scale environments was selected as first

priority. Step7 installation software is complex and

requires a dedicated installer to manage various

phases for installation and to dynamically configure

the target machine in the post-installation phase.

Allowing the system administrator to deploy,

maintain, and upgrade installations of Step7

software both remotely and in an automated fashion

on a set of target machines was thus a challenging

objective.

The team first conducted a CERN-wide survey of

PLC developers to learn about their deployment

scenarios and the possible solutions they might have

adopted to achieve this. Secondly, analysis and

evaluations of off-the-shelf tools for software

inventory management were conducted, and CFEngine

was selected as a test candidate to deploy and

automate the installation on a set of target

machines. Then, various deployment strategies were

evaluated spanning both short-term, medium-term and

long-term durations to keep in line with the

software development life-cycle of version 11 of

Step7. The team developed the prototypes for each of

these strategies and identified not only pros and

cons of each approach, but also highlighted their

impact on Step7 architecture and design to fully

utilize the benefits of software deployment tools.

All these design changes were reported to Siemens.

Finally, a strategy using Siemens Installer engine

was selected as a way forward to automate the

deployment of Step7 software that fits both with

Siemens’ short-term and long-term goals. The fact

that this strategy was approved by Siemens to be

part of their next version of Step7 software is one

of the fruitful outcomes of this collaboration.